Mutsetse weKugadzira Stamping unopisa unomhanya kwazvo weSimbi Yesimba Yakanyanya (Aluminium)

Zvinhu zvikuru

Mutsetse wekugadzira wakagadzirirwa kugadzirisa maitiro ekugadzira zvikamu zvemotokari kuburikidza nekushandisa tekinoroji yekupisa. Maitiro aya, anozivikanwa sekupisa kupisa muAsia uye kuomarara kwekudhinda muEurope, anosanganisira kupisa zvinhu zvisina chinhu kusvika patembiricha chaiyo wozozvidzvanya muzviumbwa zvinoenderana uchishandisa tekinoroji ye hydraulic press uku uchichengetedza kumanikidzwa kuti uwane chimiro chaunoda uye kuchinja simbi nenzira yekuchinja. Maitiro ekupisa kupisa anogona kupatsanurwa kuita nzira dzekupisa dzakanangana nedzisina kunanga.

Zvakanakira

Chimwe chezvakanakira zvikuru zvezvikamu zvekuvaka zvine stampu dzinopisa ndiko kugona kwazvo kugadzira, izvo zvinoita kuti pave nekugadzirwa kwemajiometri akaomarara ane simba guru rekudhonza. Simba guru rezvikamu zvine stampu dzinopisa rinobvumira kushandiswa kwemachira esimbi akatetepa, zvichideredza huremu hwezvikamu ukuwo zvichichengetedza kusimba kwechimiro uye kushanda kwekuputika. Zvimwe zvakanakira zvinosanganisira:

Kuderedzwa Kwekushanda Kwekubatanidza:Tekinoroji yekuisa zvidhinha zvinopisa inoderedza kudiwa kwekubatanidza simbi kana kusungirirwa, zvichiita kuti kushanda zvakanaka kuve nani uye kuvimbika kwechigadzirwa kuwedzere.

Springback neWarpage zvakaderedzwa:Maitiro ekuisa chisimbiso mumoto anoderedza kukanganisika kusingadiwe, senge chikamu che springback ne warpage, zvichiita kuti zvive nyore kuyera mativi acho uye kuderedza kudiwa kwekugadzirisazve.

Zvikanganiso Zvishoma zveZvikamu:Zvikamu zvine stampu dzinopisa zvinoratidza zvikanganiso zvishoma, zvakaita sekutsemuka nekutsemuka, zvichienzaniswa nenzira dzekugadzira zvinhu zvinotonhora, zvichikonzera kunaka kwechigadzirwa uye kuderera kwemarara.

Tonnage yeLower Press:Kuisa chidhindo chekupisa kunoderedza huwandu hwematani anodiwa ekudhinda zvichienzaniswa nehunyanzvi hwekugadzira zvinhu zvinotonhora, zvichiita kuti pave nekuchengetedza mari uye kuwedzera kushanda zvakanaka kwekugadzira.

Kugadzirisa Zvinhu Zvine Hunhu Hwazvo:Tekinoroji yekupisa inobvumidza kugadziriswa kwezvinhu zvichienderana nenzvimbo dzakatarwa dzechikamu, zvichiita kuti mashandiro azvo uye mashandiro azvo zvibudirire.

Kuvandudzwa Kwezvinhu Zvidiki:Kuisa chidhindo chekupisa kunopa mukana wekuvandudza chimiro chechinhu chacho, zvichikonzera kuvandudzika kwehunhu hwemakanika uye kugara kwenguva refu kwechigadzirwa.

Matanho Ekugadzira Akarongeka:Kuisa chitambi chinodziya kunobvisa kana kuderedza matanho epakati ekugadzira, zvichiita kuti maitiro ekugadzira ave nyore, kugadzirwa kwakawedzerwa, uye nguva pfupi yekutungamira ipfupi.

Zvishandiso zveChigadzirwa

Mutsetse weHigh-Strength Steel (Aluminum) High-Speed Hot Stamping Production Line unoshandiswa zvakanyanya mukugadzira zvikamu zvemuviri zvemotokari. Izvi zvinosanganisira mapillar assemblies, mabumpers, magonhi emusuwo, uye marongerwo edenga remba anoshandiswa mumotokari dzevatakuri. Pamusoro pezvo, kushandiswa kwemhando yepamusoro inogoneswa nekupisa stamping kuri kuongororwa zvakanyanya mumaindasitiri akadai semuchadenga, dziviriro, uye misika iri kubuda. Aya ma alloys anopa mabhenefiti esimba rakawanda uye huremu hwakaderera izvo zvakaoma kuwana kuburikidza nedzimwe nzira dzekugadzira.

Mukupedzisa, Mutsetse weHigh-Strength Steel (Aluminum) High-Speed Hot Stamping Production Line unovimbisa kugadzirwa kwakanyatsonaka uye kwakanaka kwezvikamu zvemuviri zvemotokari zvine chimiro chakaoma. Nekusimba kwakanyanya, kushanda kwakaderera kwekubatana, zvikanganiso zvishoma, uye hunhu hwezvinhu zvakavandudzwa, mutsetse uyu wekugadzira une mabhenefiti akawanda. Mashandisirwo awo anosvika pakugadzira zvikamu zvichena zvemuviri zvemotokari dzinotakura vanhu uye anopa mabhenefiti anogona kuitika mundege, dziviriro, uye misika iri kubuda. Isa mari muMutsetse weHigh-Strength Steel (Aluminum) High-Speed Hot Stamping Production Line kuti uwane mabhenefiti akanaka ekushanda, kubereka, uye dhizaini yakareruka muindasitiri dzemotokari nemakambani akabatana.

Chii chinonzi kupisa (hot stamping)?

Kupisa kunodziya, kunozivikanwawo sekuti press hardening muEurope uye hot press forming muAsia, inzira yekugadzira zvinhu apo gomba rinopiswa kusvika patembiricha yakati wobva wadzvanywa wodzimwa pasi pekumanikidzwa mudiyi inoenderana kuti uwane chimiro chaunoda uye kukonzera shanduko muchinhu chesimbi. Tekinoroji yekupisa inodziya inosanganisira kupisa machira esimbi eboron (ane simba rekutanga re500-700 MPa) kuenda kunzvimbo yekuomesa, nekukurumidza kuaendesa kudiyi kuti anyatso simbisa, uye kudzima chikamu chiri mukati mediyi nekutonhora kuri kupfuura 27°C/s, zvichiteverwa nenguva yekubata pasi pekumanikidzwa, kuti uwane zvikamu zvesimbi zvine simba rakawanda zvine chimiro chakafanana chemartensitic.

Zvakanakira zvekupisa stamping

Kusimba kwesimba rekupedzisira uye kugona kugadzira majometri akaomarara.

Kuderedza huremu hwechikamu nekushandisa simbi yakatetepa uku uchichengetedza chimiro chakasimba uye mashandiro ekudonha.

Kudzikira kwekuda kwekubatanidza mashandiro akaita sekunamira kana kusungirira.

Chikamu chakaderedzwa chemusana uye chakakombama.

Zvikanganiso zvishoma muzvikamu zvakaita sekutsemuka nekutsemuka.

Zvinodiwa zve press tonnage zvishoma zvichienzaniswa nekugadzira cold.

Kukwanisa kugadzirisa hunhu hwezvinhu zvichienderana nenzvimbo dzakatarwa.

Zvivakwa zve microstructures zvakavandudzwa kuti zvishande zvakanaka.

Maitiro ekugadzira akareruka uye matanho mashoma ekushanda kuti chigadzirwa chipedzwe.

Mabhenefiti aya anobatsira mukushanda zvakanaka, mhando, uye mashandiro ezvikamu zvechivakwa zvinopisa.

Mamwe mashoko nezve hot stamping

1. Kupisa Kutsika vs Kutonhora Kutsika

Kuisa chisimbiso pamoto inzira yekuumba inoitwa mushure mekudziisa simbi, nepo kuisa chisimbiso pamoto kuchireva kuisa chisimbiso chakananga chesimbi pasina kudziisa.

Kuisa chisimbiso muchando kune zvakanakira zvakajeka pane kuisa chisimbiso muchando. Zvisinei, kunoratidzawo zvimwe zvakunokanganisa. Nekuda kwekumanikidzwa kwakanyanya kunokonzerwa nemaitiro ekuisa chisimbiso muchando zvichienzaniswa nekuisa chisimbiso muchando, zvigadzirwa zvakaiswa chisimbiso muchando zviri nyore kutsemuka nekutsemuka. Nokudaro, michina chaiyo yekuisa chisimbiso inodiwa pakuisa chisimbiso muchando.

Kuisa chisimbiso chinodziya kunosanganisira kupisa simbi kusvika pakupisa kwakanyanya usati waisa chisimbiso uye kudzima panguva imwe chete mudhishi. Izvi zvinotungamira kushanduko yakakwana yechimiro chesimbi kuita martensite, zvichikonzera simba guru kubva pa1500 kusvika 2000 MPa. Nekuda kweizvozvo, zvigadzirwa zvakaiswa chisimbiso chinodziya zvinoratidza simba rakawanda zvichienzaniswa nezvimwe zvakaiswa chisimbiso chinotonhora.

2. Kuyerera kweKupisa kweKutsika

Kupisa nekupisa, kunozivikanwawo se "press hardening," kunosanganisira kupisa pepa rine simba guru rine simba rekutanga re500-600 MPa kusvika patembiricha iri pakati pe880 ne950°C. Pepa rinopisa rinozobva radhindwa nekukasika uye radzimwa mudhishi, zvichiita kuti kutonhora kusvike 20-300°C/s. Kushandurwa kweaustenite kuita martensite panguva yekudzima kunowedzera simba rechikamu, zvichibvumira kugadzirwa kwezvikamu zvakadhindwa zvine simba reanosvika 1500 MPa. Maitiro ekupisa anogona kuiswa muzvikamu zviviri: kupinza nekupisa zvakananga uye kupinza nekupisa zvisina kunanga:

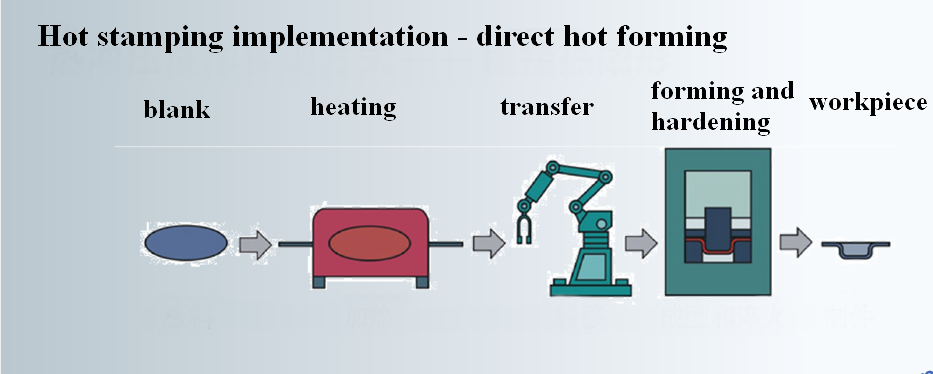

Mukugadzirisa zvakananga nekupisa, jira rakapiswa rinoiswa zvakananga mudhishi rakavharwa kuti risimbiswe nekudzima. Maitiro anotevera anosanganisira kutonhora, kuchekerera mucheto nekuboora maburi (kana kucheka ne laser), uye kuchenesa pamusoro pechinhu.

Fiture1: nzira yekugadzirisa kudzvanya kunopisa --kudzvanya zvakananga kunopisa

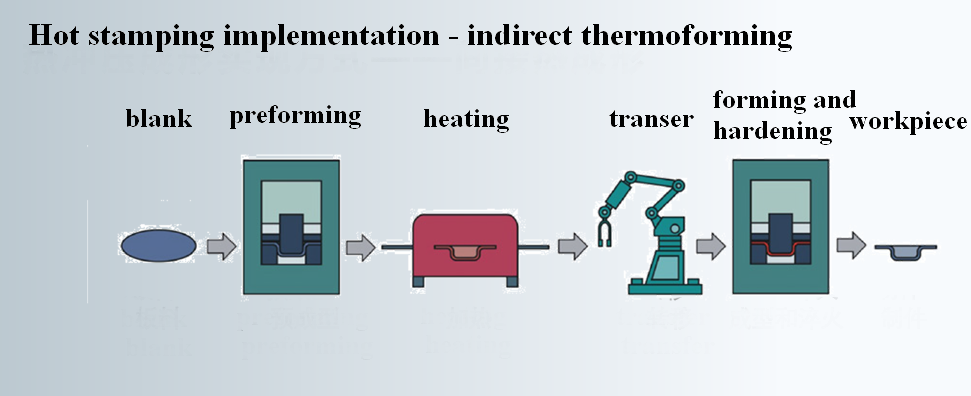

Mukuita kwekuisa chitofu chinopisa zvisina kunanga, danho rekutanga rekuisa chitofu chinopisa rinoitwa usati wapinda muzvikamu zvekudziisa, kuisa chitofu chinopisa, kuchekerera mucheto, kupwanya maburi, uye kuchenesa pamusoro pechinhu.

Musiyano mukuru uripo pakati pekuita indirect hot stamping ne direct hot stamping uripo mukuiswa kwedanho rekutanga kugadzira cold pre-shaping usati wapisa nenzira isina kunanga. Mukutsika zvakananga kupisa, sheet metal inopinzwa zvakananga muchoto chekupisa, nepo mukutsika zvakananga kupisa, chinhu chakaumbwa nechando chakaumbwa kare chinotumirwa muchoto chekupisa.

Kufamba kwemaitiro ekuisa simbi inopisa zvisina kunanga kunowanzo sanganisira matanho anotevera:

Kugadzira zvinhu zvinotonhora zvisati zvagadzirwa -- Kupisa - Kutsika-Kupisa -- Kucheka mativi uye kuboora maburi - Kuchenesa pamusoro

Fiture2: maitiro ekugadzirisa kudzvanya kunopisa -- kudzvanya kunopisa zvisina kunanga

3. Midziyo mikuru yekupisa inosanganisira chitofu chekudziisa, muchina wekupisa, uye mold dzekupisa

Choto Chekudziisa:

Choto chinodziya chine simba rekudzora kupisa uye tembiricha. Chinokwanisa kupisa maplate ane simba rakawanda kusvika pakupisa kwe recrystallization mukati menguva yakatarwa, zvichiita kuti chive che austenitic. Chinofanira kukwanisa kuchinjika kune zvinodiwa zvekugadzirwa zvinoitwa otomatiki zvakanyanya. Sezvo billet inodziya ichigona kubatwa chete nemarobhoti kana maoko emakanika, choto chinoda kurodha nekuburitsa otomatiki nekunyatsoisa nzvimbo yacho. Pamusoro pezvo, pakupisa maplate esimbi asina kuputirwa, chinofanira kupa dziviriro yegesi kudzivirira oxidation yepamusoro uye decarbonization ye billet.

Muchina Wekushongedza Unopisa:

Muchina wekudhinda ndiwo musimboti wetekinoroji yekupisa. Unofanirwa kuva nekukwanisa kupinza nekubatisisa nekukurumidza, pamwe nekuve nesystem yekutonhodza nekukurumidza. Kuomarara kwehunyanzvi hwemichina yekupisa kunodarika kure kwemichina yemazuva ano yekupisa. Parizvino, makambani mashoma ekunze chete ndiwo akaziva dhizaini nehunyanzvi hwekugadzira michina yakadaro, uye ese anovimba nekutenga zvinhu zvinotengeswa kunze kwenyika, zvichiita kuti zvidhure.

Mafomu Ekudzikisa Anopisa:

Zviumbwa zvinopisa zvinoshandisa matanho ekuumba uye ekudzima. Padanho rekugadzira, kana billet yaiswa mugomba rechiumbwa, chiumbwa chinokurumidza kupedza maitiro ekumisa kuti chive nechokwadi chekuti chikamu chapera kugadzirwa zvisati zvapinda mukuchinja kwechikamu chemartensitic. Zvadaro, chinopinda muchikamu chekudzima nekutonhodza, uko kupisa kubva pachinhu chebasa chiri mukati mechiumbwa kunoramba kuchiendeswa kuchiumbwa. Mapaipi ekutonhodza akarongwa mukati mechiumbwa anobvisa kupisa nekukurumidza kuburikidza nechinotonhodza chinoyerera. Kuchinja kwemartensitic-austenitic kunotanga kana tembiricha yechinhu chebasa yadzikira kusvika 425°C. Kuchinja pakati pemartensite neaustenite kunopera kana tembiricha yasvika 280°C, uye chinhu chebasa chinobviswa pa200°C. Basa rekubata chiumbwa ndechekudzivirira kuwedzera kwekupisa kusina kuenzana uye kudzikira panguva yekudzima, izvo zvinogona kukonzera shanduko huru muchimiro nehukuru hwechikamu, zvichikonzera kupwanyika. Pamusoro pezvo, zvinowedzera kushanda kwekupisa pakati pechinhu chebasa nechiumbwa, zvichikurudzira kudzimwa nekutonhodza nekukurumidza.

Muchidimbu, michina mikuru yekupisa inosanganisira chitofu chinodziya kuti chisvike pakupisa kwaunoda, muchina wekupisa unodzvanya nekubatirira nekukurumidza uchishandisa sisitimu yekutonhodza nekukurumidza, uye mold dzinopisa dzinoita matanho ekuumba nekudzima kuti zvive nechokwadi chekuti chikamu chakagadzirwa zvakanaka uye kuti kutonhora kunoshanda zvakanaka.

Kumhanya kwekudzima kutonhora hakungokanganisi nguva yekugadzira chete, asiwo kunokanganisa kushanda zvakanaka kwekushandura pakati peaustenite nemartensite. Kumhanya kwekutonhodza kunotarisa kuti rudzii rwechimiro chekristaro chichagadzirwa uye chine chekuita nemhedzisiro yekupedzisira yekuomesa kwechinhu chebasa. Kupisa kwekutonhodza kwakakosha kwesimbi yeboron kunenge 30℃/s, uye chete kana kutonhora kuchipfuura tembiricha yekutonhodza kwakakosha ndipo panogona kusimudzirwa kuumbwa kwechimiro chemartensitic zvakanyanya. Kana kutonhora kuri pasi pechiyero chekutonhodza kwakakosha, zvivakwa zvisiri zvemartensitic zvakaita sebainite zvichaonekwa muchimiro chekristaro chebasa. Zvisinei, kana kutonhora kuchikwira, zviri nani, kutonhora kuchikwira kunotungamira mukutsemuka kwezvikamu zvakagadzirwa, uye huwandu hwekutonhodza hwakakodzera hunofanirwa kutsanangurwa zvichienderana nekuumbwa kwezvinhu nemamiriro ekushanda kwezvikamu.

Sezvo dhizaini yepombi yekutonhodza iine chekuita zvakananga nehukuru hwekumhanya kwekutonhodza, pombi yekutonhodza inowanzo gadzirwa kubva pamaonero ekushanda kwakanyanya kwekupisa, saka divi repombi yekutonhodza rakagadzirwa rakaoma, uye zvakaoma kuwana nekuboorera nemechanical mushure mekupedza kuumbwa kwemold. Kuti zvisave zvakaganhurirwa nekugadzirwa kwemechanical, nzira yekuchengetedza nzira dzemvura usati wagadzirwa nemold casting inowanzo sarudzwa.

Nekuti inoshanda kwenguva yakareba pa200℃ kusvika 880~950℃ pasi pemamiriro ekutonhora kwakanyanya uye kupisa kwakasiyana-siyana, chinhu chinobatidza moto chinofanira kunge chakasimba uye chinofambisa kupisa zvakanaka, uye chinogona kuramba kukweshana kwakasimba kwekupisa kunokonzerwa nebillet pakupisa kwakanyanya uye abrasive wear effect yezvidimbu zve dropped oxide layer. Pamusoro pezvo, chinhu chinobatidza chinofanirawo kuva nekudzivirira kwakanaka kwengura kune chinotonhodza kuti chive nechokwadi chekuti pombi inotonhodza inoyerera zvakanaka.

Kucheka nekuboora

Nekuti simba rezvikamu mushure mekupiswa rinosvika pa1500MPa, kana kudhinda nekupwanya zvikashandiswa, zvinodiwa zve tonnage yemidziyo zvakakura, uye kupera kwemucheto we die kwakakomba. Saka, mayuniti ekucheka ne laser anowanzo shandiswa kucheka mipendero nemaburi.

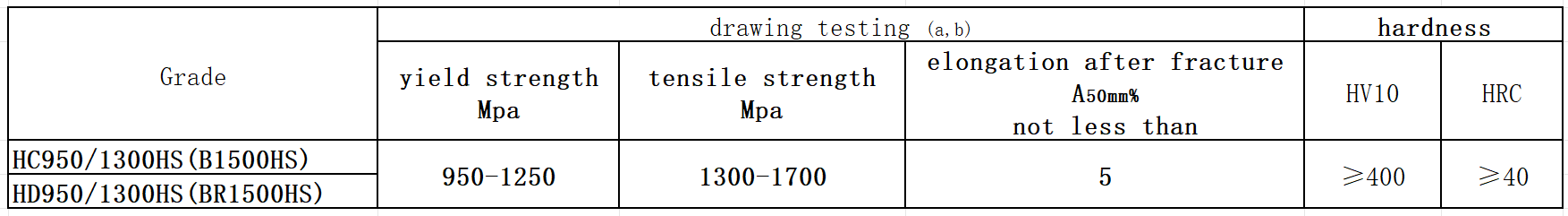

4.Common mamakisi esimbi inopisa yekusimbisa

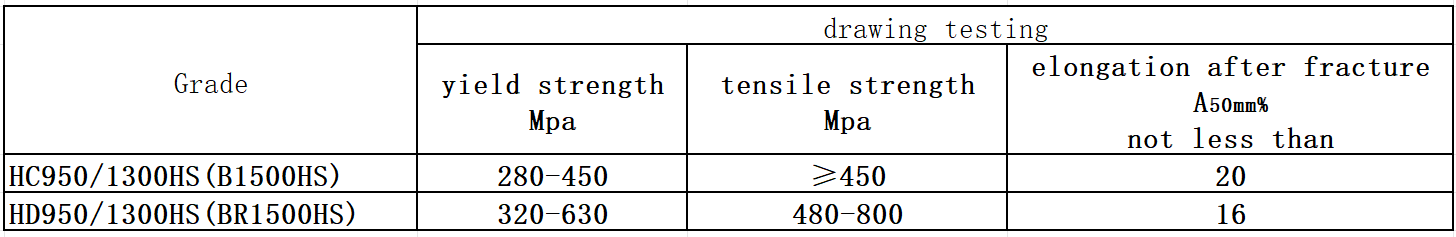

Kushanda usati waisa chidhindo

Kushanda mushure mekudhindwa

Parizvino, simbi inopiswa inoshandiswa zvakanyanya iB1500HS. Simba rekudhonza risati raiswa rinowanzova pakati pe480-800MPa, uye mushure mekudhonza, simba rekudhonza rinogona kusvika 1300-1700MPa. Kureva kuti, simba rekudhonza resimbi ye480-800MPa, kuburikidza nekudhonza kunopisa, rinogona kuwana simba rekudhonza rinenge 1300-1700MPa zvikamu.

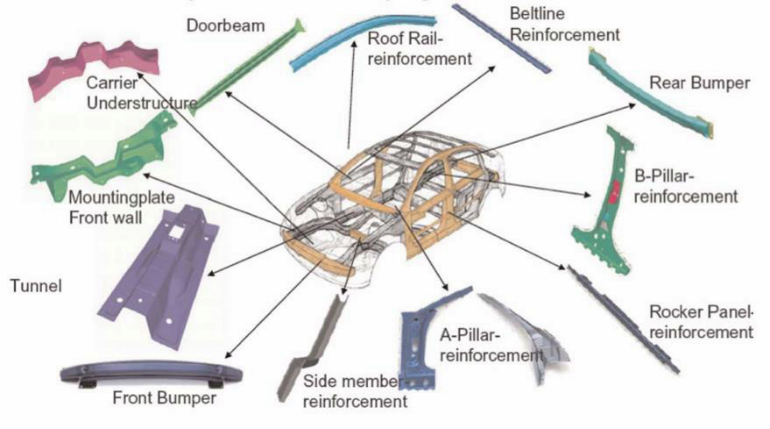

5. Kushandiswa kwesimbi inopisa yekutsika

Kushandiswa kwezvikamu zvinopisa zvinogona kuvandudza kuchengetedzeka kwemotokari uye kuita kuti muviri wemotokari uve muchena. Parizvino, tekinoroji yekupisa yave kushandiswa kuzvikamu zvichena zvemuviri wemotokari dzevatakuri, zvakaita semota, A pillar, B pillar, bumper, door beam ne roof rail nezvimwe zvikamu. Ona mufananidzo 3 pazasi semuenzaniso zvikamu zvakakodzera kuyera.

Mufananidzo 3: Zvikamu zvemuviri muchena zvakakodzera kupiswa

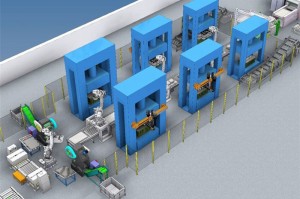

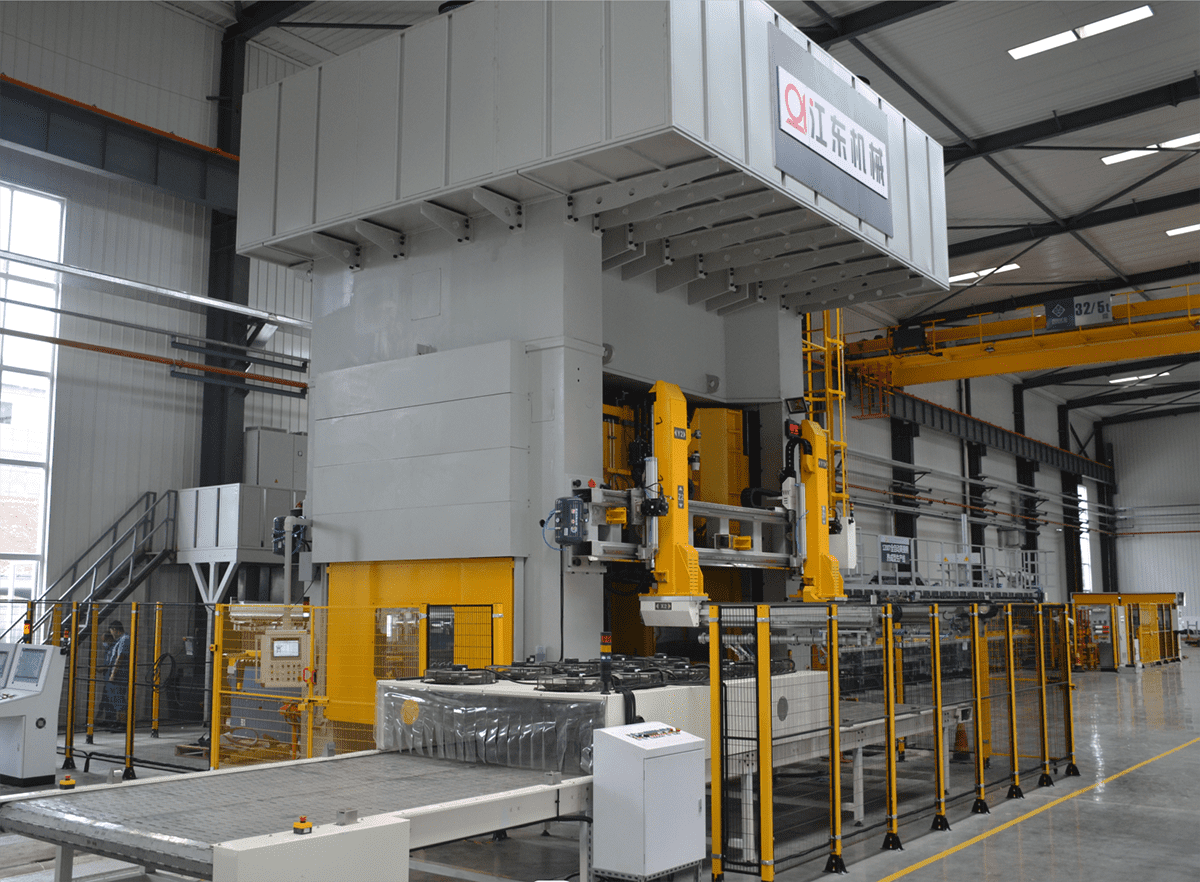

Mufananidzo 4: Michina yeJiangdong ine 1200 Ton Hot Stamping Press Line

Parizvino, mhinduro dzeJiangdong Machinery dzekugadzira michina ye hydraulic press dzakakura uye dzakagadzikana, mumunda wekugadzira michina ye hydraulic press muChina ndewepamusoro, uye semutevedzeri wesachigaro weChina Machine Tools Association pamwe chete nenhengo dzeChina Forging Machinery Standardization Committee, takaitawo tsvakiridzo nekushandiswa kwebasa renyika re super high speed hot stamping resimbi nealuminium, iro rakaita basa guru mukusimudzira indasitiri yekupisa muChina uye kunyangwe pasi rose.